Artificial Intelligence Applications in Manufacturing

In the manufacturing market, machine vision has become an important part of many artificial intelligence applications. As artificial intelligence enters the manufacturing shop floor, these standards become especially critical

Across multiple markets driving vision applications, a key trend is ease of use. Sophisticated cameras, sensors and processing technologies have evolved into plug-and-play solutions. We introduce the same approach to the field of artificial intelligence in manufacturing. Our goal is to simplify AI so organizations can start deploying new technology to save time and money. What we provide is a platform of artificial intelligence and vision-based inspection and traceability applications that can easily customize unique workflows to make manufacturing decisions consistent, reliable and traceable

What are some common misconceptions about the use of artificial intelligence in manufacturing?

One of the biggest misconceptions is that it is complicated. This was true a few years ago, but recently there has been an emphasis on making AI tools simpler and easier to use. Our position is that you don’t need to be an expert to develop your own AI algorithms or digital workflows. With user-friendly drag-and-drop development tools and customizable app-based templates, anyone can develop their own AI-based workflows. This is a huge advantage for manufacturers, avoiding vendor lock-in and duplicative integration and development costs

What types of problems can artificial intelligence solve?

Machine vision is good at pass/fail decisions, but it is difficult to manually program acceptable tolerances. In contrast, artificial intelligence can be more easily trained to learn these variable decisions. The example I used was hardwood inspection. It is very difficult to manually program machine vision to discern natural textures and scratches. By comparison, it's much easier to train an AI based on a few good and bad images so that it can recognize the difference. Basically, due to its learning capabilities, AI can help in making subjective decisions.

There are also great opportunities for AI in inspection processes that rely on human decision-making. AI can help us make the right decisions on subjective quality decisions, or catch errors when our attention starts to shift. We're working with an auto parts manufacturer that relies on manual inspection but is adding artificial intelligence assistance to spot defects that may have been missed or determine if defects are within operating tolerances

Visual inspection technology that leverages artificial intelligence can help auto parts manufacturers identify errors and determine whether defects are within acceptable performance tolerances

How today’s manufacturers use labor Intelligent?

#One key area where manufacturers are deploying artificial intelligence is around human decision support. Despite significant investment in manufacturing automation, approximately 70% of processes in the United States still require human decision-making. This is especially true for small-scale, custom or seasonal production, which is too expensive and complex to invest in full automation.

Rewritten content: Visual inspection is an area where artificial intelligence helps humans make correct decisions. As part of a camera-based system, visual inspection applications can highlight product differences or defects to aid operators in inspection. At the same time, this is also an area where we can use the initial decisions of operators when dealing with these defects to train artificial intelligence models to solve the problem of previous misunderstandings. As operators accept or reject these initial differences, they are effectively training the AI model transparently. After multiple inspections, the AI model will begin to provide decision-making recommendations to the operator , including product images and operator instructions to provide full traceability to the manual process. For example, we work with an electronics manufacturer that assembles parts for high-reliability applications, and having complete end-to-end inspection steps and records of operator decisions is critical for traceability.

Dica Electronics uses visual inspection as a “second pair of eyes” to catch potential production errors, while also capturing a complete record of product images and operator notes to ensure traceability. Decca Electronics uses visual inspection as a "second pair of eyes" to catch potential production errors and simultaneously records product images and operator notes to ensure traceability

You're right Any suggestions on how manufacturers can deploy AI?

There is a lot of hype around AI, and manufacturers often build expectations based on perfect use cases. Soon, they ran into a problem. Their application may not be as simple as that perfect use case. A lot of customization is required. A common problem is simply getting the images needed to build and train an AI model—especially if you’re making a unique, low-volume product.

Usually our advice is to digitize the process first and then gradually move towards automation. Visual inspection is a great starting point, where you first use machine vision to detect errors and then add AI-based decision support to extend consistent decision-making across shifts or across different workstations. When you digitize your first error-prone process, you are capturing data that can help guide your next automated decisions. Typically this is adding traceability to visual inspection decisions or incorporating guided work or assembly instructions into the inspection process.

Overall, pick an error-prone process and see how you can use digitization and AI to save you time and money. We are working with many manufacturers who started pilot projects around the first troublesome defect or process, became comfortable with the technology, and are now scaling it across different workstations or production lines.

What is the biggest obstacle to using artificial intelligence in manufacturing?

This is a major issue that is often overlooked, don’t forget it People

Even with automation, many processes still require human decision-making at some point. This could be as simple as explaining to operators why a process is being automated and providing the necessary training so they can apply their expertise in new ways. For example, in robotic welding applications, the goal is to remove humans from repetitive, dirty, and dangerous tasks but still rely on their expert insight and years of training to monitor the process and evaluate the results. Without proper communication and training, humans will quickly abandon technology and resist change. This is who we are

Looking ahead to the next few years, what do you think the application of artificial intelligence in manufacturing will look like? How will Pleora be involved?

Not long ago, people were generally afraid of artificial intelligence. However, this widespread concern is largely disappearing. This is thanks to artificial intelligence technology becoming easier to use and becoming more common in our daily lives. It amazes me that I now leave a lot of decisions to a virtual assistant on my smartphone

We are at the same point in manufacturing. Just a few years ago, AI was expensive and complex, mostly limited to advanced laboratories, but development tools now make it easier for quality managers to design and deploy their own AI-assisted workflows. There is also greater focus on how artificial intelligence technology can help the human workforce, freeing them from boring, dirty and dangerous tasks and assisting them in decision-making

in the manufacturing market The key to widespread adoption of these technologies is making them more accessible to end users. This is our primary focus; providing quality managers with customizable, easy-to-deploy solutions that enable them to reduce manufacturing errors and costs.

The above is the detailed content of Artificial Intelligence Applications in Manufacturing. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

Bytedance Cutting launches SVIP super membership: 499 yuan for continuous annual subscription, providing a variety of AI functions

Jun 28, 2024 am 03:51 AM

Bytedance Cutting launches SVIP super membership: 499 yuan for continuous annual subscription, providing a variety of AI functions

Jun 28, 2024 am 03:51 AM

This site reported on June 27 that Jianying is a video editing software developed by FaceMeng Technology, a subsidiary of ByteDance. It relies on the Douyin platform and basically produces short video content for users of the platform. It is compatible with iOS, Android, and Windows. , MacOS and other operating systems. Jianying officially announced the upgrade of its membership system and launched a new SVIP, which includes a variety of AI black technologies, such as intelligent translation, intelligent highlighting, intelligent packaging, digital human synthesis, etc. In terms of price, the monthly fee for clipping SVIP is 79 yuan, the annual fee is 599 yuan (note on this site: equivalent to 49.9 yuan per month), the continuous monthly subscription is 59 yuan per month, and the continuous annual subscription is 499 yuan per year (equivalent to 41.6 yuan per month) . In addition, the cut official also stated that in order to improve the user experience, those who have subscribed to the original VIP

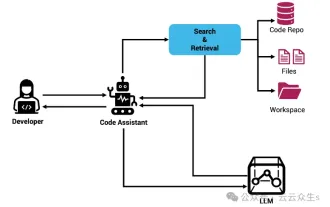

Context-augmented AI coding assistant using Rag and Sem-Rag

Jun 10, 2024 am 11:08 AM

Context-augmented AI coding assistant using Rag and Sem-Rag

Jun 10, 2024 am 11:08 AM

Improve developer productivity, efficiency, and accuracy by incorporating retrieval-enhanced generation and semantic memory into AI coding assistants. Translated from EnhancingAICodingAssistantswithContextUsingRAGandSEM-RAG, author JanakiramMSV. While basic AI programming assistants are naturally helpful, they often fail to provide the most relevant and correct code suggestions because they rely on a general understanding of the software language and the most common patterns of writing software. The code generated by these coding assistants is suitable for solving the problems they are responsible for solving, but often does not conform to the coding standards, conventions and styles of the individual teams. This often results in suggestions that need to be modified or refined in order for the code to be accepted into the application

Seven Cool GenAI & LLM Technical Interview Questions

Jun 07, 2024 am 10:06 AM

Seven Cool GenAI & LLM Technical Interview Questions

Jun 07, 2024 am 10:06 AM

To learn more about AIGC, please visit: 51CTOAI.x Community https://www.51cto.com/aigc/Translator|Jingyan Reviewer|Chonglou is different from the traditional question bank that can be seen everywhere on the Internet. These questions It requires thinking outside the box. Large Language Models (LLMs) are increasingly important in the fields of data science, generative artificial intelligence (GenAI), and artificial intelligence. These complex algorithms enhance human skills and drive efficiency and innovation in many industries, becoming the key for companies to remain competitive. LLM has a wide range of applications. It can be used in fields such as natural language processing, text generation, speech recognition and recommendation systems. By learning from large amounts of data, LLM is able to generate text

Can fine-tuning really allow LLM to learn new things: introducing new knowledge may make the model produce more hallucinations

Jun 11, 2024 pm 03:57 PM

Can fine-tuning really allow LLM to learn new things: introducing new knowledge may make the model produce more hallucinations

Jun 11, 2024 pm 03:57 PM

Large Language Models (LLMs) are trained on huge text databases, where they acquire large amounts of real-world knowledge. This knowledge is embedded into their parameters and can then be used when needed. The knowledge of these models is "reified" at the end of training. At the end of pre-training, the model actually stops learning. Align or fine-tune the model to learn how to leverage this knowledge and respond more naturally to user questions. But sometimes model knowledge is not enough, and although the model can access external content through RAG, it is considered beneficial to adapt the model to new domains through fine-tuning. This fine-tuning is performed using input from human annotators or other LLM creations, where the model encounters additional real-world knowledge and integrates it

Five schools of machine learning you don't know about

Jun 05, 2024 pm 08:51 PM

Five schools of machine learning you don't know about

Jun 05, 2024 pm 08:51 PM

Machine learning is an important branch of artificial intelligence that gives computers the ability to learn from data and improve their capabilities without being explicitly programmed. Machine learning has a wide range of applications in various fields, from image recognition and natural language processing to recommendation systems and fraud detection, and it is changing the way we live. There are many different methods and theories in the field of machine learning, among which the five most influential methods are called the "Five Schools of Machine Learning". The five major schools are the symbolic school, the connectionist school, the evolutionary school, the Bayesian school and the analogy school. 1. Symbolism, also known as symbolism, emphasizes the use of symbols for logical reasoning and expression of knowledge. This school of thought believes that learning is a process of reverse deduction, through existing

To provide a new scientific and complex question answering benchmark and evaluation system for large models, UNSW, Argonne, University of Chicago and other institutions jointly launched the SciQAG framework

Jul 25, 2024 am 06:42 AM

To provide a new scientific and complex question answering benchmark and evaluation system for large models, UNSW, Argonne, University of Chicago and other institutions jointly launched the SciQAG framework

Jul 25, 2024 am 06:42 AM

Editor |ScienceAI Question Answering (QA) data set plays a vital role in promoting natural language processing (NLP) research. High-quality QA data sets can not only be used to fine-tune models, but also effectively evaluate the capabilities of large language models (LLM), especially the ability to understand and reason about scientific knowledge. Although there are currently many scientific QA data sets covering medicine, chemistry, biology and other fields, these data sets still have some shortcomings. First, the data form is relatively simple, most of which are multiple-choice questions. They are easy to evaluate, but limit the model's answer selection range and cannot fully test the model's ability to answer scientific questions. In contrast, open-ended Q&A

SK Hynix will display new AI-related products on August 6: 12-layer HBM3E, 321-high NAND, etc.

Aug 01, 2024 pm 09:40 PM

SK Hynix will display new AI-related products on August 6: 12-layer HBM3E, 321-high NAND, etc.

Aug 01, 2024 pm 09:40 PM

According to news from this site on August 1, SK Hynix released a blog post today (August 1), announcing that it will attend the Global Semiconductor Memory Summit FMS2024 to be held in Santa Clara, California, USA from August 6 to 8, showcasing many new technologies. generation product. Introduction to the Future Memory and Storage Summit (FutureMemoryandStorage), formerly the Flash Memory Summit (FlashMemorySummit) mainly for NAND suppliers, in the context of increasing attention to artificial intelligence technology, this year was renamed the Future Memory and Storage Summit (FutureMemoryandStorage) to invite DRAM and storage vendors and many more players. New product SK hynix launched last year

SOTA performance, Xiamen multi-modal protein-ligand affinity prediction AI method, combines molecular surface information for the first time

Jul 17, 2024 pm 06:37 PM

SOTA performance, Xiamen multi-modal protein-ligand affinity prediction AI method, combines molecular surface information for the first time

Jul 17, 2024 pm 06:37 PM

Editor | KX In the field of drug research and development, accurately and effectively predicting the binding affinity of proteins and ligands is crucial for drug screening and optimization. However, current studies do not take into account the important role of molecular surface information in protein-ligand interactions. Based on this, researchers from Xiamen University proposed a novel multi-modal feature extraction (MFE) framework, which for the first time combines information on protein surface, 3D structure and sequence, and uses a cross-attention mechanism to compare different modalities. feature alignment. Experimental results demonstrate that this method achieves state-of-the-art performance in predicting protein-ligand binding affinities. Furthermore, ablation studies demonstrate the effectiveness and necessity of protein surface information and multimodal feature alignment within this framework. Related research begins with "S