Scientists 3D print high-precision plasma sensors for satellites

According to reports, the Massachusetts Institute of Technology in the United States has recently developed a 3D printed precision plasma sensor. The device is low-cost and easy to manufacture. These digital devices can help scientists predict weather or study climate change. The plasma sensors, also known as "Retarded Potential Analyzers (RPAs)," are used by orbiting spacecraft such as Sputnik to determine the chemical composition of the atmosphere and the distribution of ion energy.

Semiconductor plasma sensors are manufactured through 3D printing and laser cutting processes. Since the process requires a dust-free environment, the semiconductor plasma sensors are expensive and require several weeks to complete. Complex manufacturing process. By comparison, MIT's latest plasma sensor takes just a few days to make and costs tens of dollars.

Because of its lower cost and speed of production, this new sensor is an ideal choice for CubeSats, which are low-cost, low-power and lightweight and are often used for communications and environmental monitoring in the Earth's upper atmosphere.

The research team developed a new type of plasma sensor using glass ceramic materials that are more elastic than traditional sensor materials such as silicon and thin film coatings. By using glass ceramics in the plastic 3D printing process, they can create complex shapes. sensors that can withstand the huge temperature fluctuations a spacecraft may encounter in low-Earth orbit.

Luis Fernando Velasquez-Garcia, senior author of the study and chief scientist at MIT’s Microsystems Technology Laboratory (MTL), said: “Additive manufacturing It will have a major impact in the field of future space hardware. Some people believe that when 3D printing some objects, they must accept lower performance, but we have now proved that this is not always the case." The latest research report was published recently Published in the Journal of Additive Manufacturing.

Multifunctional Sensor

Plasma sensors were first used in space missions in 1959. They can detect the energy of ions or charged particles floating in plasma, which exists on the earth. A mixture of superheated molecules in the upper atmosphere. On orbiting spacecraft like CubeSats, plasma sensors can measure changes in energy and conduct chemical analyses, helping scientists predict weather or monitor climate change.

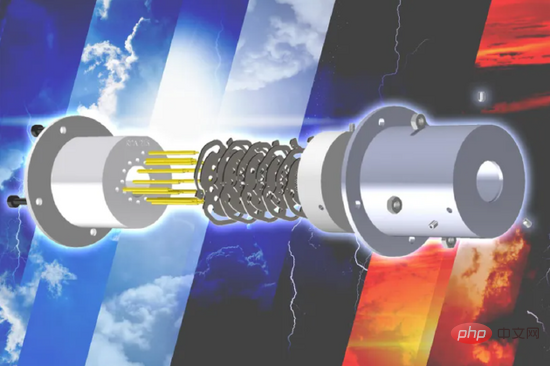

The sensor contains a series of charged grids filled with small holes. When the plasma passes through the small holes, electrons and other particles will be stripped away until only ions remain. When these ions generate an electric current, the sensor will Measure and analyze it.

The key to successful plasmonic sensor applications is an aligned grid of hole-like structures, which must be electrically insulating while being able to withstand drastic temperature swings. The researchers used a 3D-printable glass-ceramic material— —Vitrolite, which meets the above characteristics. It is reported that Vitrolite material first appeared in the early 20th century and was often used in colorful ceramic tile designs, becoming the most common material in Art Deco architecture.

The durable Vitrolite material can withstand temperatures up to 800 degrees Celsius without decomposing, while the polymer materials in integrated circuit-structured plasma sensors begin to melt at 400 degrees Celsius. "When workers build this sensor in a clean room, they won't have the same freedom to define the materials and structure and how they interact," Garcia said, "but that could lead to the latest developments in additive manufacturing." .”

Re-understanding the 3D printing process of plasma sensors

The 3D printing process of ceramic materials usually involves laser bombardment of ceramic powder to fuse it into various shaped structures. However, due to the laser release With its high heat, this manufacturing process tends to roughen the material and create blemishes.

However, the MIT scientists used reductive polymerization in the manufacturing process, a process introduced decades ago that uses polymers or resins for additive manufacturing. In the reduction polymerization technology, the material is repeatedly immersed in a reduction tank containing Vitrolite liquid material. Once immersed, a layer of three-dimensional structure will be formed. After each layer of structure is formed, the material is cured with ultraviolet light. Each layer of the structure is only 100 microns thick. (equivalent to the diameter of a human hair), and eventually repeatedly immersed in the Vitrolite liquid material, a smooth, non-porous, complex ceramic structure will be formed.

In the digital manufacturing process, the manufacturing objects described in the design documents may be very complex. This high-precision design requires researchers to use a laser-cut mesh with a unique structure, which is installed on the plasma sensor housing after printing is completed. The small hole-like structure can be perfectly arranged to allow more ions to pass through it, thereby obtaining higher-precision measurement data.

Because the sensor is low-cost and fast to produce, the research team produced four unique design prototypes. One design prototype is particularly effective at capturing and measuring large-scale plasmas, especially for satellite orbital survey plasmas, and the other design prototype is well-suited for measuring extremely high-density, extremely cold plasmas, which is usually only possible in Ultra-precision semiconductor device measurements.

This high-precision design could enable 3D printed sensors to be used in fusion energy research or supersonic flight, and Garcia added that this fast 3D printing process could even lead to more innovations in satellite and spacecraft design.

Garcia said: "If you want to continue to innovate, you have to face failure and take the corresponding risks. Additive manufacturing is another way to make space equipment. We can make space devices, even if the process If it fails, it doesn’t matter because we can still make a new version quickly and cheaply and iterate on the design. For researchers, this is an ideal sandbox effect.”

It is reported that although Garcia is very satisfied with the latest design of the plasma sensor, he hopes to continuously improve the manufacturing process in the future and reduce the layer thickness or pixel size during the glass-ceramic cylinder polymerization process, thereby creating a more accurate sensor. complex device. In addition, the fully additive manufacturing process can make them continuously compatible with space manufacturing. He also hopes to explore the use of artificial intelligence to continuously optimize sensor design to adapt to specific application scenarios, such as significantly reducing sensor weight while ensuring structural stability.

The above is the detailed content of Scientists 3D print high-precision plasma sensors for satellites. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

AI optimized design, thermal resistance reduced by 2.3C / 100W, Asetek cooperates with Fabric8Labs to launch new cold head

Jun 06, 2024 pm 12:59 PM

AI optimized design, thermal resistance reduced by 2.3C / 100W, Asetek cooperates with Fabric8Labs to launch new cold head

Jun 06, 2024 pm 12:59 PM

According to news from this website on June 3, water cooling solution provider Asetek announced that it has cooperated with metal 3D printing company Fabric8Labs to launch a new AI-optimized cold head, which will be displayed at the ASUS ROG booth at Computex 2024 Taipei International Computer Show. Compared with previous generations of water cooling solutions, the AI-optimized cold head uses artificial intelligence and ECAM additive manufacturing technology to improve heat dissipation performance in an "unprecedented" way by optimizing fluid dynamics. According to reports, the official used complex AI simulation tools to build the entire cold head structure. The fins are different in design and can only be manufactured using 3D printing processes. This website noticed that compared with Asetek’s eighth-generation solution, the original AI-optimized cold head design can reduce the thermal resistance by 2.3C/1

Which computer should Geographic Information Science majors choose?

Jan 13, 2024 am 08:00 AM

Which computer should Geographic Information Science majors choose?

Jan 13, 2024 am 08:00 AM

Recommended computers suitable for students majoring in geographic information science 1. Recommendation 2. Students majoring in geographic information science need to process large amounts of geographic data and conduct complex geographic information analysis, so they need a computer with strong performance. A computer with high configuration can provide faster processing speed and larger storage space, and can better meet professional needs. 3. It is recommended to choose a computer equipped with a high-performance processor and large-capacity memory, which can improve the efficiency of data processing and analysis. In addition, choosing a computer with larger storage space and a high-resolution display can better display geographic data and results. In addition, considering that students majoring in geographic information science may need to develop and program geographic information system (GIS) software, choose a computer with better graphics processing support.

New 'AI scientists” combine theory and data to discover scientific equations

May 18, 2023 am 10:49 AM

New 'AI scientists” combine theory and data to discover scientific equations

May 18, 2023 am 10:49 AM

Scientists aim to discover meaningful formulas that accurately describe experimental data. Mathematical models of natural phenomena can be created manually based on domain knowledge, or they can be created automatically from large data sets using machine learning algorithms. The academic community has studied the problem of merging related prior knowledge and related function models, and believes that finding a model that is consistent with prior knowledge of general logical axioms is an unsolved problem. Researchers from the IBM research team and Samsung AI team developed a method "AI-Descartes" that combines logical reasoning with symbolic regression to conduct principled derivation of natural phenomenon models from axiomatic knowledge and experimental data. The study is based on "Combining data and theory for

Multiple drones collaborate to 3D print a house, and the research appears on the cover of Nature

Apr 09, 2023 am 11:51 AM

Multiple drones collaborate to 3D print a house, and the research appears on the cover of Nature

Apr 09, 2023 am 11:51 AM

We can often see bees, ants and other animals busy building nests. After natural selection, their work efficiency is astonishingly high. The ability of these animals to divide and cooperate has been "passed on" to drones. A study from Imperial College London shows us the future direction, like this: Unmanned Aerial Vehicles Machine 3D dust removal: This Wednesday, this research result appeared on the cover of "Nature". Paper address: https://www.nature.com/articles/s41586-022-04988-4 To demonstrate the capabilities of drones, the researchers used foam and a special lightweight cement material to build a structure with a height ranging from 0.18 meters to structures ranging from 2.05 meters. Original blueprint with vision

'Father of Machine Learning' Mitchell writes: How AI accelerates scientific development and how the United States seizes opportunities

Jul 29, 2024 pm 08:23 PM

'Father of Machine Learning' Mitchell writes: How AI accelerates scientific development and how the United States seizes opportunities

Jul 29, 2024 pm 08:23 PM

Editor | ScienceAI Recently, Tom M. Mitchell, a professor at Carnegie Mellon University and known as the "Father of Machine Learning," wrote a new AI for Science white paper, focusing on "How does artificial intelligence accelerate scientific development? How does the U.S. government Help achieve this goal? ” theme. ScienceAI has compiled the full text of the original white paper without changing its original meaning. The content is as follows. The field of artificial intelligence has made significant recent progress, including large-scale language models such as GPT, Claude, and Gemini, thus raising the possibility that a very positive impact of artificial intelligence, perhaps greatly accelerating

96 Chinese scholars were selected as the world's top 1,000 computer scientists, and Zhang Lei became the first in mainland China

Apr 21, 2023 pm 06:58 PM

96 Chinese scholars were selected as the world's top 1,000 computer scientists, and Zhang Lei became the first in mainland China

Apr 21, 2023 pm 06:58 PM

Recently, Research (Guide2Research) released the ranking of the world's top 1,000 computer scientists in 2023. 583 American scientists dominate the list. There are 96 Chinese scientists on the list, with Zhang Lei ranking first among mainland Chinese scientists. Among the top 20 scientists in the world, there are many big names in AI, such as Turing Award winners Bengio and Hinton. Netizens pointed out that among the top 100 computer scientists in the United States, there are only 7 women. Research’s ranking of the best scientists in computer science has been updated to its 9th edition. This ranking reviewed various academic indicators of more than 14,400 scientists around the world and selected the top 1,000 top scientists. Ranking based on including O

Science's annual top ten scientific research announcements: the Webb telescope was selected, accompanied by AIGC!

Apr 11, 2023 pm 03:37 PM

Science's annual top ten scientific research announcements: the Webb telescope was selected, accompanied by AIGC!

Apr 11, 2023 pm 03:37 PM

Finally, the 2022 Science Magazine’s biggest awards are announced! On December 16, the science official website released the "Top Ten Scientific Breakthroughs in 2022", among which the Webb Telescope won the crown and was published on the cover of the latest issue. The reason for the award given by Science magazine is: Due to its technical feats of construction and launch and its huge prospects for exploring the universe, the James Webb Telescope was named Science Magazine's 2022 Scientific Breakthrough of the Year. In addition, major achievements in the scientific community in the past year, including AIGC, NASA's successful impact on an asteroid, and Yunnan University's creation of perennial rice, have also been selected. Let’s review these blockbuster studies over the past year. Breakthrough of the Year—Webb Telescope July 12, NA

What are the pros and cons of implementing artificial intelligence in healthcare?

Apr 12, 2023 pm 10:34 PM

What are the pros and cons of implementing artificial intelligence in healthcare?

Apr 12, 2023 pm 10:34 PM

Artificial intelligence in healthcare covers a wide range of things that can help health systems and workers, but what are the specific benefits and drawbacks of adopting AI? From transportation to service delivery, artificial intelligence (AI) has demonstrated science and technology over the years developments, especially with the implementation of AI in healthcare. However, it doesn't stop there. One of its biggest leaps forward has been in health care, which has elicited mixed reactions among the general public and medical professionals. Artificial intelligence in healthcare encompasses a broad range of assistance with algorithms and tedious tasks that are part of a healthcare worker's job. This includes streamlining time-consuming tasks, streamlining complex procedures, and even real-time clinical decision-making. But like all aspects of human progress, in order to see the bigger picture