Technology peripherals

Technology peripherals

AI

AI

MIT's latest achievement: This 'self-replicating' robot can build everything from airplanes to rockets!

MIT's latest achievement: This 'self-replicating' robot can build everything from airplanes to rockets!

MIT's latest achievement: This 'self-replicating' robot can build everything from airplanes to rockets!

How outrageous are the abilities of today’s robots?

It’s really unimaginable. Even building airplanes and rockets has become a small case. They can even build themselves! Really promising.

Recently, a paper by MIT researchers was published in the journal Nature Communications Engineering.

The paper was co-published by Center for Bits and Atoms (CBA) doctoral student Amira Abdel-Rahman, professor and CBA director Neil Gershenfeld, and three others who have made significant progress in creating robots. Results.

Paper address: https://www. php.cn/link/1b742ae215adf18b75449c6e272fd92d

It is understood that the latest robot developed by Gershenfeld’s research team can assemble almost anything quickly and effectively. Including objects much larger than yourself, from vehicles to buildings to larger robots and more.

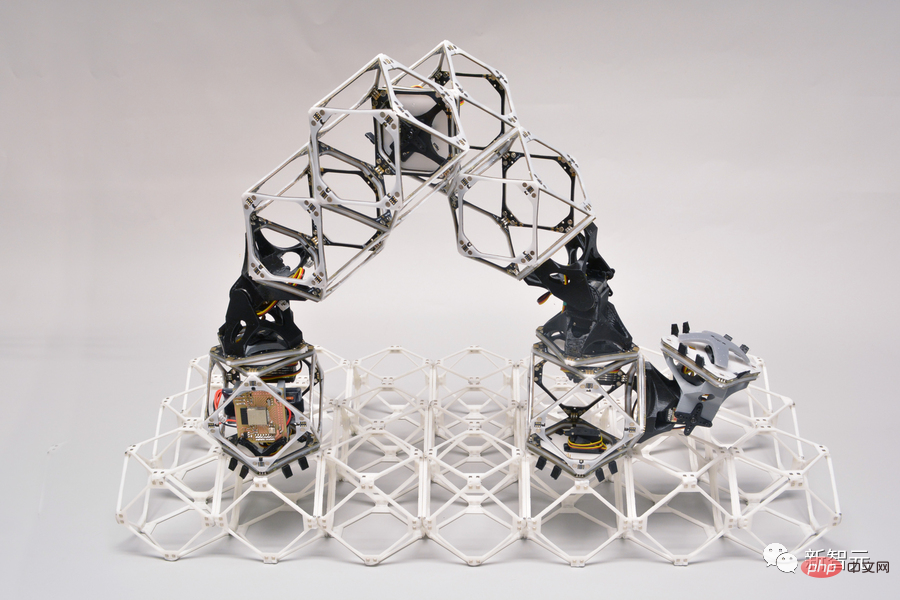

The team has shown that both the assembly robots and the structural components being built can be composed of the same subunits, and that the robots can operate independently in large numbers Move quickly to complete large-scale assembly.

Based on the standardized design of the same structure, this also means that this robot can "effortlessly" assemble a new version of itself.

"Constructing a self-replicating system is not only a classic challenge in #, but even a classic in science fiction literature Challenge," said Sandor Fekete, professor of algorithms at the Department of Computer Science at the Technical University of Braunschweig in Germany. "So far, only nature has truly achieved this. So their work is very exciting People’s hearts!」

The “big dream” of small voxels

Voxel is a very tiny sub-unit, equivalent to the volume component of a two-dimensional pixel. As with previous experiments, the new system involves large, usable structures built from voxel arrays.

However, unlike the voxels of early mechanical structures, the voxels used by Gershenfeld's research team are more "complex", and can be made from one unit Carry power and data to the next unit.

This allows the structure to be built not only to withstand loads, but also to lift, move and manipulate materials - even the voxels themselves.

Early versions of assembly robots had bundles of wires connected to their power and control systems, Gershenfeld said, but “we built the These structures create an "intelligent system" that allows voxels to transmit power, data, and power regardless of wires."

The robot itself consists of a string of several voxels connected end-to-end. These voxels can grab hold of another voxel using a connection point at one end, then move like a worm to the desired location, attach to the growing structure and release there.

Robot path optimization algorithm, the world’s first

Gershenfeld explained that while the early systems demonstrated by his group members could in principle build arbitrarily large structures, the process becomes more complex when the size of those structures reaches a certain size compared to the size of the assembly robots. It is becoming more and more inefficient, "because each robot must take a longer path to bring the parts to the destination."

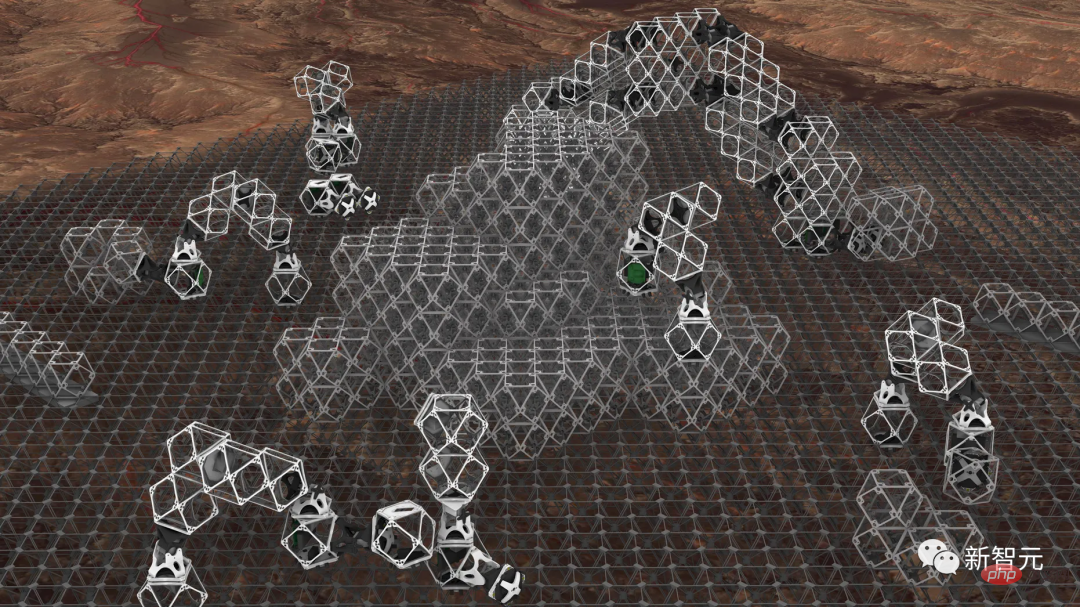

With their newly developed system, the robot can decide Whether to build a larger version that can reach greater distances and reduce "commute" time.

Building a larger structure may require another such step. Bigger robots are created from new, larger robots, while building finely detailed structures may require more help from the smallest robots.

Abdel-Rahman said that when these robotic devices work on assembling things, they face choices every step of the way.

"It can build a structure, it can build another robot of the same size, it can also build a larger robot."

"We have been working on creating a decision optimization algorithm for this part of the work."

"For example, If you want to build a cone or a hemisphere," she said, "how do you start path planning and how do you divide that shape into different areas where different robots can work?"

The software they developed allows someone to input a shape and get an output that shows where to place the first block, and every block after that, based on the distance that needs to be traversed.

Gershenfeld said that although there have been thousands of papers published on robot route planning, “the next steps, when the robot must When making a decision, building another robot or a different kind of robot, This is a completely new job, and there is no precedent to refer to."

Research Limitations

While the experimental system can be assembled and include power and data links, in its current version the connectors between the tiny sub-units are still not strong enough , unable to bear the necessary load. Miana Smith, a graduate student on the team, is working on developing more powerful connectors.

Gershenfeld said: "These robots can walk and they can place parts, but we haven't reached the point where one robot builds another robot and then it's gone."

"To make this situation a reality, we also need the support of some emerging technologies, such as the power of actuators and the strength of joints."

MIT computer scientist Neil Gershenfeld

##Gershenfeld also said that a fully autonomous self-replicating robot assembly system is both Being able to assemble larger structures, including larger robots, and plan the best construction sequence - This may still take a few years.

But this work is already an important step toward that goal, including solving the complex tasks of when to build more robots, how big of a robot to make, and How to organize robots of different sizes to build a structure in an orderly manner.

From airplanes to rockets, the application potential of new technologies is huge

The application potential of this achievement is huge, because it is likely to be used tobuild various large-scale, High value structure.

For example, now when building an aircraft, you first need a huge factory, the factory is even much larger than the parts they are building, plus other aircraft may often be needed to transport manufacturing raw materials needed for aircraft.

With such a system of tiny parts assembled by microrobots, "the final assembly of the aircraft will become the only assembly process," Gershenfeld said .

Similarly, in building a car, "you might spend a year building the tooling" before the first car is actually built, he said, but with the new system The emergence of will obviously bypass this process.

This potential efficiency is why Gershenfeld and his students have been working closely with car companies, airlines and aerospace agencies.

Even the relatively low-tech construction industry is likely to benefit from this technology in the future.

Interest in 3D printed homes has grown in recent years, but these homes now require printing machines that are as large or larger than the homes being built. The use of such micro-robots can apparently effectively solve this problem.

Aaron Becker, associate professor in the Department of Electrical and Computer Engineering at the University of Houston, gave the work the highest possible rating, calling it 『Home run』:

"They have created an innovative hardware system, a new way of thinking about expanding the robot population. method, and a rigorous set of algorithms."

"This paper examines a key area of reconfigurable systems: how to rapidly scale a robotic workforce and use it to efficiently Assemble the materials into the required structure."

"This is the first time I have seen such work!"

The above is the detailed content of MIT's latest achievement: This 'self-replicating' robot can build everything from airplanes to rockets!. For more information, please follow other related articles on the PHP Chinese website!

Hot AI Tools

Undresser.AI Undress

AI-powered app for creating realistic nude photos

AI Clothes Remover

Online AI tool for removing clothes from photos.

Undress AI Tool

Undress images for free

Clothoff.io

AI clothes remover

Video Face Swap

Swap faces in any video effortlessly with our completely free AI face swap tool!

Hot Article

Hot Tools

Notepad++7.3.1

Easy-to-use and free code editor

SublimeText3 Chinese version

Chinese version, very easy to use

Zend Studio 13.0.1

Powerful PHP integrated development environment

Dreamweaver CS6

Visual web development tools

SublimeText3 Mac version

God-level code editing software (SublimeText3)

Hot Topics

The second generation Ameca is here! He can communicate with the audience fluently, his facial expressions are more realistic, and he can speak dozens of languages.

Mar 04, 2024 am 09:10 AM

The second generation Ameca is here! He can communicate with the audience fluently, his facial expressions are more realistic, and he can speak dozens of languages.

Mar 04, 2024 am 09:10 AM

The humanoid robot Ameca has been upgraded to the second generation! Recently, at the World Mobile Communications Conference MWC2024, the world's most advanced robot Ameca appeared again. Around the venue, Ameca attracted a large number of spectators. With the blessing of GPT-4, Ameca can respond to various problems in real time. "Let's have a dance." When asked if she had emotions, Ameca responded with a series of facial expressions that looked very lifelike. Just a few days ago, EngineeredArts, the British robotics company behind Ameca, just demonstrated the team’s latest development results. In the video, the robot Ameca has visual capabilities and can see and describe the entire room and specific objects. The most amazing thing is that she can also

After 2 months, the humanoid robot Walker S can fold clothes

Apr 03, 2024 am 08:01 AM

After 2 months, the humanoid robot Walker S can fold clothes

Apr 03, 2024 am 08:01 AM

Editor of Machine Power Report: Wu Xin The domestic version of the humanoid robot + large model team completed the operation task of complex flexible materials such as folding clothes for the first time. With the unveiling of Figure01, which integrates OpenAI's multi-modal large model, the related progress of domestic peers has been attracting attention. Just yesterday, UBTECH, China's "number one humanoid robot stock", released the first demo of the humanoid robot WalkerS that is deeply integrated with Baidu Wenxin's large model, showing some interesting new features. Now, WalkerS, blessed by Baidu Wenxin’s large model capabilities, looks like this. Like Figure01, WalkerS does not move around, but stands behind a desk to complete a series of tasks. It can follow human commands and fold clothes

How can AI make robots more autonomous and adaptable?

Jun 03, 2024 pm 07:18 PM

How can AI make robots more autonomous and adaptable?

Jun 03, 2024 pm 07:18 PM

In the field of industrial automation technology, there are two recent hot spots that are difficult to ignore: artificial intelligence (AI) and Nvidia. Don’t change the meaning of the original content, fine-tune the content, rewrite the content, don’t continue: “Not only that, the two are closely related, because Nvidia is expanding beyond just its original graphics processing units (GPUs). The technology extends to the field of digital twins and is closely connected to emerging AI technologies. "Recently, NVIDIA has reached cooperation with many industrial companies, including leading industrial automation companies such as Aveva, Rockwell Automation, Siemens and Schneider Electric, as well as Teradyne Robotics and its MiR and Universal Robots companies. Recently,Nvidiahascoll

The first robot to autonomously complete human tasks appears, with five fingers that are flexible and fast, and large models support virtual space training

Mar 11, 2024 pm 12:10 PM

The first robot to autonomously complete human tasks appears, with five fingers that are flexible and fast, and large models support virtual space training

Mar 11, 2024 pm 12:10 PM

This week, FigureAI, a robotics company invested by OpenAI, Microsoft, Bezos, and Nvidia, announced that it has received nearly $700 million in financing and plans to develop a humanoid robot that can walk independently within the next year. And Tesla’s Optimus Prime has repeatedly received good news. No one doubts that this year will be the year when humanoid robots explode. SanctuaryAI, a Canadian-based robotics company, recently released a new humanoid robot, Phoenix. Officials claim that it can complete many tasks autonomously at the same speed as humans. Pheonix, the world's first robot that can autonomously complete tasks at human speeds, can gently grab, move and elegantly place each object to its left and right sides. It can autonomously identify objects

The humanoid robot can do magic, let the Spring Festival Gala program team find out more

Feb 04, 2024 am 09:03 AM

The humanoid robot can do magic, let the Spring Festival Gala program team find out more

Feb 04, 2024 am 09:03 AM

In the blink of an eye, robots have learned to do magic? It was seen that it first picked up the water spoon on the table and proved to the audience that there was nothing in it... Then it put the egg-like object in its hand, then put the water spoon back on the table and started to "cast a spell"... …Just when it picked up the water spoon again, a miracle happened. The egg that was originally put in disappeared, and the thing that jumped out turned into a basketball... Let’s look at the continuous actions again: △ This animation shows a set of actions at 2x speed, and it flows smoothly. Only by watching the video repeatedly at 0.5x speed can it be understood. Finally, I discovered the clues: if my hand speed were faster, I might be able to hide it from the enemy. Some netizens lamented that the robot’s magic skills were even higher than their own: Mag was the one who performed this magic for us.

Cloud Whale Xiaoyao 001 sweeping and mopping robot has a 'brain'! | Experience

Apr 26, 2024 pm 04:22 PM

Cloud Whale Xiaoyao 001 sweeping and mopping robot has a 'brain'! | Experience

Apr 26, 2024 pm 04:22 PM

Sweeping and mopping robots are one of the most popular smart home appliances among consumers in recent years. The convenience of operation it brings, or even the need for no operation, allows lazy people to free their hands, allowing consumers to "liberate" from daily housework and spend more time on the things they like. Improved quality of life in disguised form. Riding on this craze, almost all home appliance brands on the market are making their own sweeping and mopping robots, making the entire sweeping and mopping robot market very lively. However, the rapid expansion of the market will inevitably bring about a hidden danger: many manufacturers will use the tactics of sea of machines to quickly occupy more market share, resulting in many new products without any upgrade points. It is also said that they are "matryoshka" models. Not an exaggeration. However, not all sweeping and mopping robots are

Ten humanoid robots shaping the future

Mar 22, 2024 pm 08:51 PM

Ten humanoid robots shaping the future

Mar 22, 2024 pm 08:51 PM

The following 10 humanoid robots are shaping our future: 1. ASIMO: Developed by Honda, ASIMO is one of the most well-known humanoid robots. Standing 4 feet tall and weighing 119 pounds, ASIMO is equipped with advanced sensors and artificial intelligence capabilities that allow it to navigate complex environments and interact with humans. ASIMO's versatility makes it suitable for a variety of tasks, from assisting people with disabilities to delivering presentations at events. 2. Pepper: Created by Softbank Robotics, Pepper aims to be a social companion for humans. With its expressive face and ability to recognize emotions, Pepper can participate in conversations, help in retail settings, and even provide educational support. Pepper's

Is robotic IoT the future of manufacturing?

Mar 01, 2024 pm 06:10 PM

Is robotic IoT the future of manufacturing?

Mar 01, 2024 pm 06:10 PM

Robotic IoT is an emerging development that promises to bring together two valuable technologies: industrial robots and IoT sensors. Will the Internet of Robotic Things become mainstream in manufacturing? What is the Internet of Robotic Things? The Internet of Robotic Things (IoRT) is a form of network that connects robots to the Internet. These robots use IoT sensors to collect data and interpret their surroundings. They are often combined with various technologies such as artificial intelligence and cloud computing to speed up data processing and optimize resource utilization. The development of IoRT enables robots to sense and respond to environmental changes more intelligently, bringing more efficient solutions to various industries. By integrating with IoT technology, IoRT can not only realize autonomous operation and self-learning, but also